Skip to content

- All sizes have same ease of installation.

- Locate area for installation of Curb-O-Let.

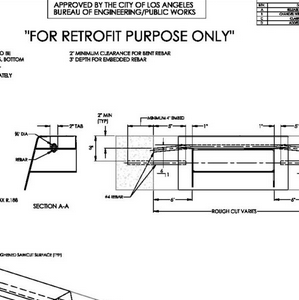

- Cut-out should be measured to include an extra 6” on each side of the Curb-O-Let flange. Cut existing curb and roughen saw cut surface.

- Drill 4” deep holes through the middle of each of the roughened saw cuts of the curb.

- Insert #4 rebar into the drilled holes using an OSHA approved adhesive. Rebar should extend from the saw cut, to the edge of the Curb-O-Let flange.

- Place Curb-O-Let nailing flange on curbside of lumber form, make sure top of Curb-O-Let is flush with top of form (this provides a self leveling effect).

- Nail Curb-O-Let to form, using holes provided on the support nailing flange (this is all the support needed).

- Insert #4 rebar into the hole provided under top of the Curb-O-Let. Rebar should extend at least 6” past each side flange. Bend rebar down 2” on each side.

- Place the face of the curb form lumber against the face of the Curb-O-Let.

- Pour concrete into form.

- After concrete is poured and cured, remove forms.

- Curb-O-Let is now an integral part of the curb and your installation is complete.